Proven Products, Proven Experience

Since 1985, Intersurface Dynamics has manufactured application-specific chemicals used to achieve specific surface morphologies on a variety of materials. Our customers include some of the world’s largest manufacturers of semiconductor devices, silicon wafers, precision optics, ophthalmic lens, ceramics, advanced displays and flat glass. These manufacturers rely on our proven products and expertise to optimize critical high-volume manufacturing.

Intersurface Dynamics’ products include three different product lines addressing the needs of each specific industry. Tensor Series Products are used by manufacturers of integrated circuits in applications such as cleaning, etching, dicing and CMP. Vector Series Products were designed specifically for grinding, sawing, lapping, cleaning, etching and polishing semiconductor materials such as silicon and SiC wafers. Challenge Series Products address similar processes for manufacturers of precision optics, technical ceramics and advanced displays, helping to achieve optimum yields. Big Blue Products are economical and easy to use, assuring quick, efficient manufacturing of flat glass and mirror products.

Advanced Manufacturing

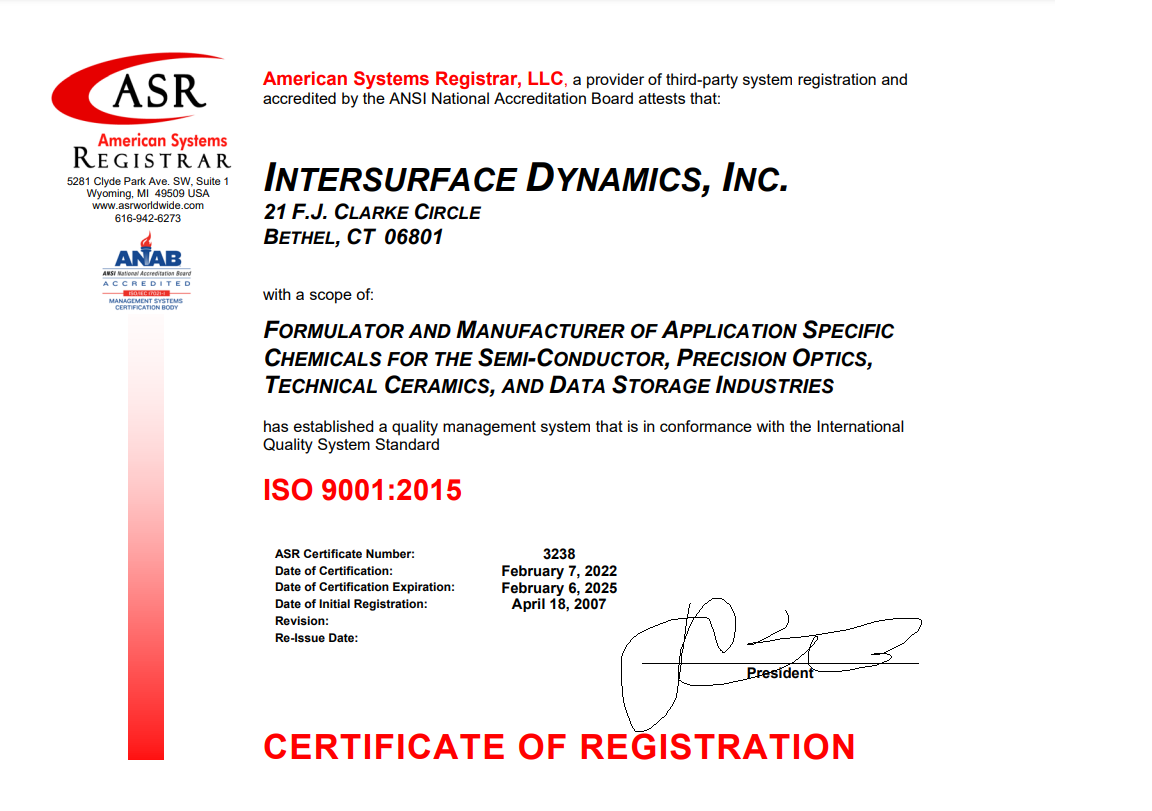

All Intersurface Dynamics products are manufactured on automated manufacturing lines with on-site chemical research facilities containing the latest analytic equipment. Our ISO-9001:2015 registered facility coupled with advanced manufacturing techniques has produced a record of excellence translating into reliable and timely service for critical process technology demands.

Product Design

Input from field engineering provides the impetus for product design, while continuous basic research in the areas of chemistry, physics and material science is the catalyst for product innovation. Worker safety and environmental compatibility are also integral to the process. This balanced approach allows us to be responsive to the needs and challenges of our customers.

Process Simulation

After a formulation is designed in the chemical research laboratory, Intersurface Dynamics completes the optimization through application testing in the process simulation laboratory. Within this lab, new potential products are tested on parts and in processes that simulate a customer’s manufacturing environment. Afterwards, using advanced metrology equipment, the results from the tests are compiled. Review of the compiled data determines if the product is ready for commercialization.