PR Series

The PR-Series of double-sided planetary lapping and polishing machines have a time-proven design. With thousands of machines built, the dependability, versatility, ease of operation, and low cost of ownership of the PR-Series machines is tough to beat. The PR machines are well-suited to laboratory, research and development, as well as production environments.

The base PR-Series machine design employs a non-rotating top and bottom plate, variable-speed outer ring gear and center sun gear drive, and down force generated by the freely floating top plate. The planetary action simultaneously removes equal amounts of material from both sides of the parts being processed.

The PR-Series machine configurations provide capability for a broad spectrum of precision processing requirements on parts that are thin and fragile, parts that have a high aspect ratio, and parts that have a low surface area. The rugged machine construction withstands harsh environments and provides a stable platform for producing flat and parallel parts. Additionally, we offer a range of optional features as well as design customization to satisfy the individual needs of our customers.

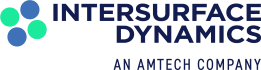

PR - 1

Equipment

- Choice of four carrier (work holder) configurations: (13) 32 tooth, (8) 50 tooth, (5) 66 tooth, or (5) 85 tooth

- Smooth cast iron plates

- Stationary bottom plate

- Floating, non-rotating top plate

- Cast iron ring and center gears

- Driven by single variable speed motor

- Mechanical transmission drives the outer ring gear and center sun gear at fixed gear ratio

- Overrunning clutch provides soft stop at end of process cycle and allows operator to manually rotate ring and center gears

- Bottom plate height adjustment mechanism

Control console

- Illuminated start/stop selector switch, master speed control knob, manual or timer control selector switch, emergency stop pushbutton and main disconnect selector switch

- Digital process cycle timer control

Provisions for raising and lowering the top plate

- Top plate handles and a post and hanger for storing the top plate on the 32T, 50T and 66T configurations

- Top plate lifting device operated by 2-hand safety control pushbuttons and pneumatic system on the 85T configuration

One year warranty

Download Brochure Request Information

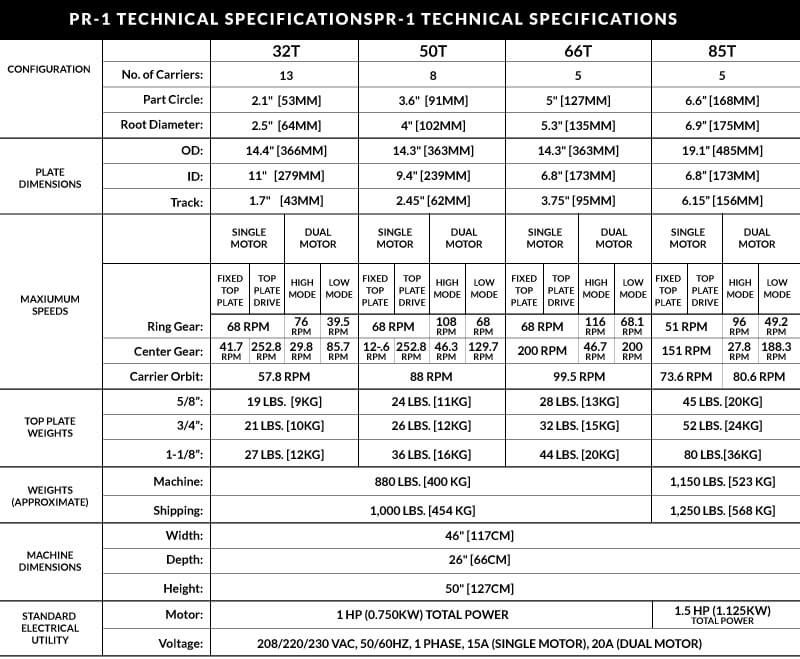

PR - 2

Equipment

- 32 tooth carrier configuration

- Smooth cast iron plates

- Stationary bottom plate

- Floating, non-rotating top plate

- Cast iron ring and center gears

- Driven by single variable speed motor

- Mechanical transmission drives the outer ring gear and center sun gear at fixed gear ratio

- Overrunning clutch provides soft stop at end of process cycle and allows operator to manually rotate ring and center gears

- Bottom plate height adjustment mechanism

- Post and hanger for storing top plate when machine is not running

Control console

- Illuminated start/stop selector switch, master speed control knob, manual or timer control selector switch, emergency stop pushbutton and main disconnect selector switch

- Digital process cycle timer control

Top plate manually raised and lowered onto parts being processed

One year warranty

Download Brochure Request Information

SERVO RS Series

In 1990, PR Hoffman introduced the Servo-RS Model 1500, the first machine in its new Servo RS™ series. The design of this machine series drew from over 50 years of experience with developing and building double-side planetary lapping and polishing machines. In the following years, we have expanded and refined the family of Servo RS TM machines to include the model 1500, 1900, 3100, 5400, 6600, and Mark-IV machines, which feature nine carrier work holder sizes that range from 2.5” [64mm] to 31.5” [800mm] in diameter.

The base machine designs in the Servo RS™ series (with the exception of the Mark-IV model*), all employ a fixed bottom plate, independently programmable rotating top plate, center gear, and ring gear, and precise, servo-controlled down force control. We also offer a counter-rotating 4-way machine design option on the 1500, 1900 and 3100 models. All machine motions incorporate advanced drive technologies for precise control and high efficiency.

In 1990, PR Hoffman introduced the Servo-RS Model 1500, the first machine in the Servo RS™ series. The design of this machine builds on 50 years of experience with developing double-side planetary lapping and polishing machines. Since then, we have expanded and refined the family of Servo RS Machines. All Servo-RS machines utilize a common motion controller and Windows PC-based software with touchscreen interface. They offer a range of optional features as well as design customization in order to enhance the individual needs of our customers.

Standard Features

- Smooth cast iron plates

- Fixed bottom plate

- Self-aligning swivel-mounted top plate

- Independently programmable top plate, ring gear, and center gear rotation using servo motor motion controls

- Stainless steel ring and center sprockets with spring pins

- Servo-controlled downforce with load cell feedback

- Retractable ring gear

- Thick-section plates and sub-plates for improved flatness and stability

Automatic slurry feed system

- Pump and mixer are remote controlled by process recipe

- Slurry tank and distribution lines, with recirculation available

- Variable speed propeller-style mixer with controls at mixer motor

- Variable speed, reversible peristaltic pump with controls at panel

Automatic flush water system and hand sprayer

- Flush water is controlled by process recipe

- Flush flow control valve and distribution lines

- Teflon hand-held sprayer

- All components are compatible with deionized water

On-site machine install, set-up, and training

One year warranty

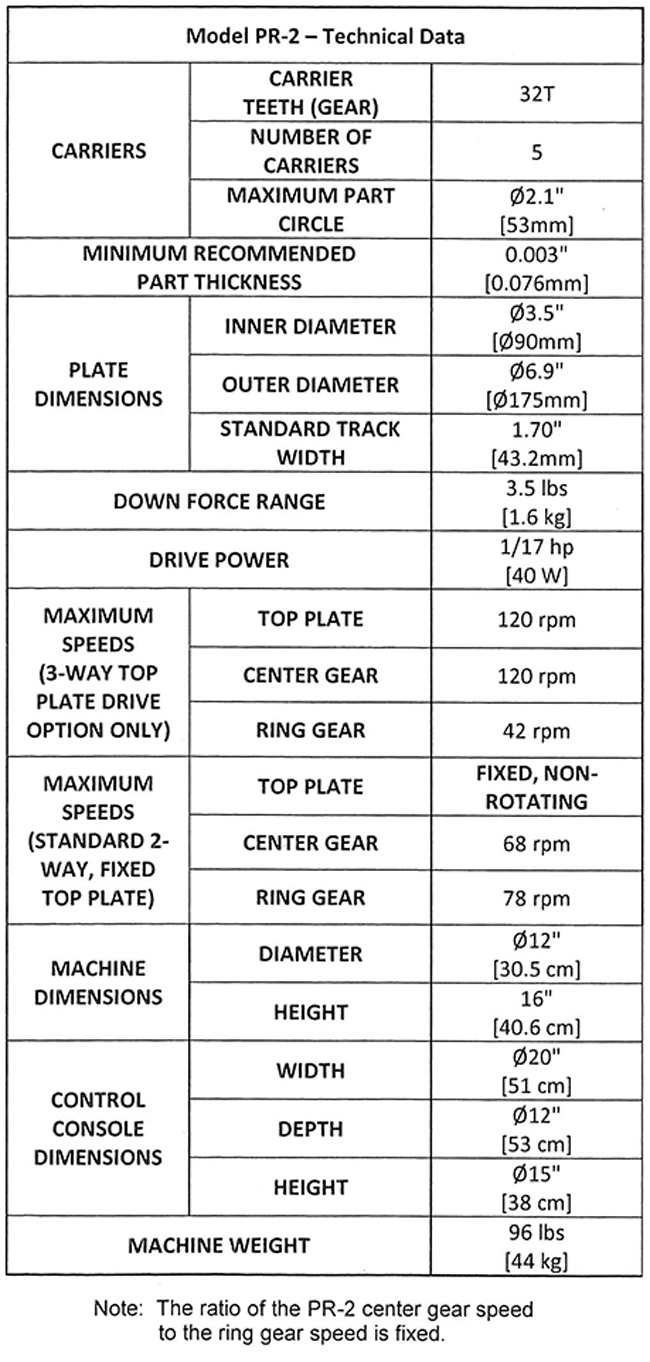

Servo RS – 1900

Counter-rotating bottom plate 4-way configuration

Plates

- Serrated cast iron for lapping

- Stainless steel for polishing or fixed abrasive lapping

- Ductile Martensite iron fine-grain lapping plates for scratch-free lapping of parts with fine particle slurry

Stainless steel ring and center gears

Digital gauge

- Thickness control for lapping

- Crash protection for lapping and polishing

Automatic Lapping Control (ALC)

Water heated and cooled bottom plate temperature control system

Slurry system

- Recirculating slurry

- Multiple or high-capacity peristaltic feed heads and distribution lines

- Centrifuge system

- Slurry tank heating and cooling system

- Variety of customizable configurations available

Chemical injection system

- Auxiliary peristaltic pump and tank system

- Chemical injection pump controlled by process recipe

Wide variety of accessories available

Download Brochure Request Information

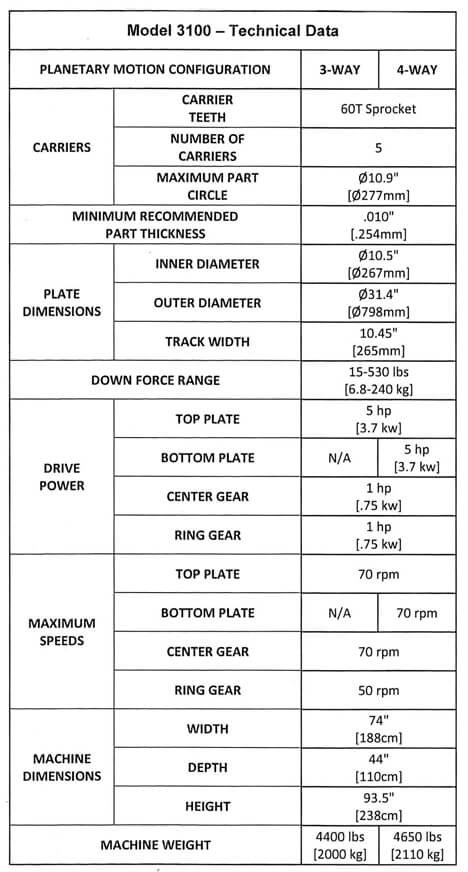

Servo RS – 3100

Counter-rotating bottom plate 4-way configuration

Plates

- Serrated cast iron for lapping

- Stainless steel for polishing or fixed abrasive lapping

Stainless steel roller pins on ring and center sprockets

Digital gauge

- Thickness control for lapping

- Crash protection for lapping and polishing

Automatic Lapping Control (ALC)

Water heated and cooled bottom plate temperature control system

Slurry system

- Recirculating slurry

- Multiple or high-capacity peristaltic feed heads and distribution lines

- Centrifuge system

- Slurry tank heating and cooling system

- Variety of customizable configurations available

Chemical injection system

- Auxiliary peristaltic pump and tank system

- Chemical injection pump controlled by process recipe

Wide variety of accessories available

Download Brochure Request Information

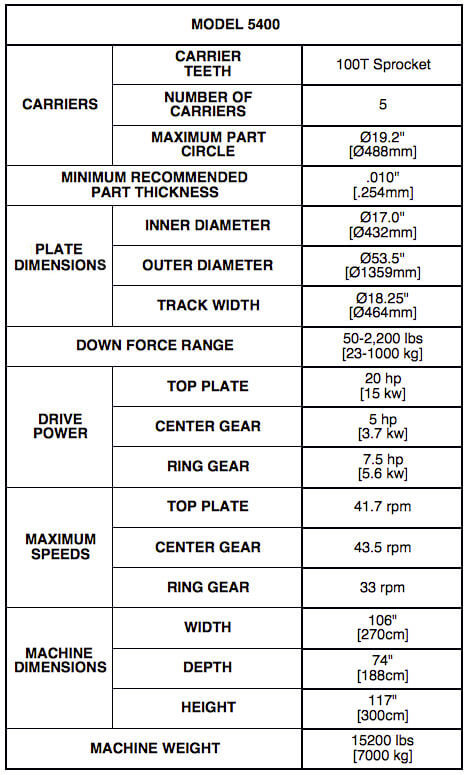

Servo RS – 5400

Plates

- Serrated cast iron for lapping

- Stainless steel for polishing or fixed abrasives

- Cast iron with stainless steel cladding and slurry inserts for polishing or fixed abrasives

- Ductile Martensite for lapping with fine abrasive

Stainless steel ring and center sprockets

Digital gauge

- Thickness control for lapping

- Crash protection for lapping and polishing

Automatic Lapping Control (ALC)

Water heated and cooled plate temperature control system for both top and bottom plates

Slurry system

- Recirculating slurry

- Multiple or high-capacity peristaltic feed heads and distribution lines

- Centrifuge system

- Slurry tank heating and cooling system

- Variety of customizable configurations available

Chemical injection system

- Auxiliary peristaltic pump and tank system

- Chemical injection pump controlled by process recipe

Wide variety of accessories available

Download Brochure Request Information

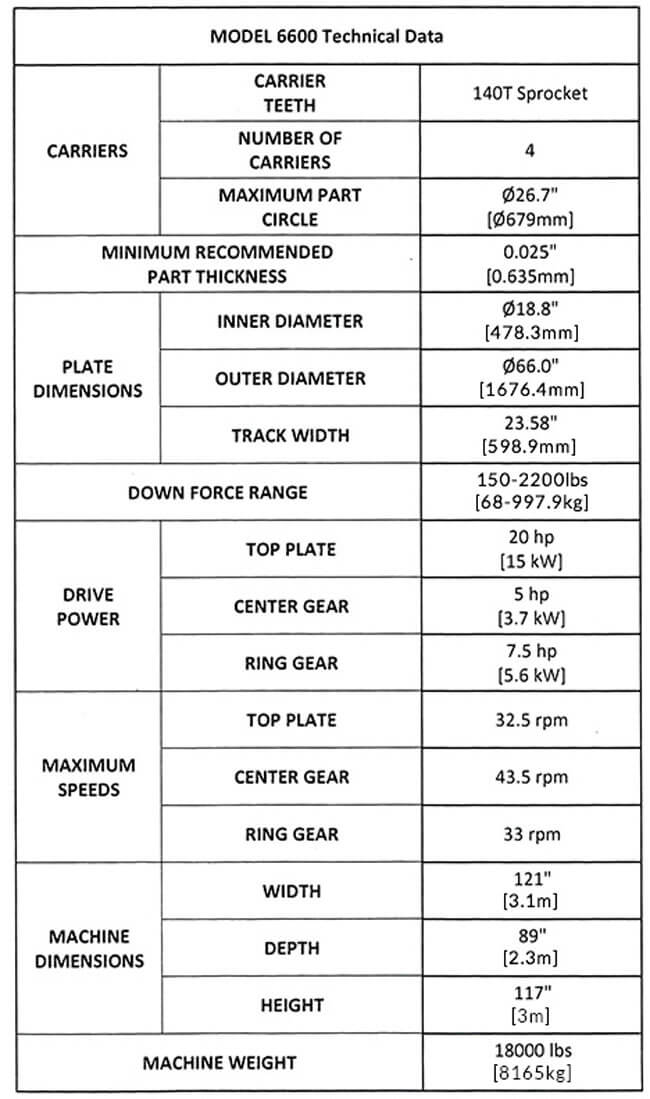

Servo RS – 6600

Plates

- Serrated cast iron for lapping

- Stainless steel for polishing or fixed abrasives

- Cast iron with stainless steel cladding and slurry inserts for polishing or fixed abrasives

- Ductile Martensite for lapping with fine abrasive

Stainless steel roller pins on ring and center sprockets

Digital gauge

- Thickness control for lapping

- Crash protection for lapping and polishing

Automatic Lapping Control (ALC)

Water heated and cooled plate temperature control system for both top and bottom plates

Slurry system

- Recirculating slurry

- Multiple or high-capacity peristaltic feed heads and distribution lines

- Centrifuge system

- Slurry tank heating and cooling system

- Variety of customizable configurations available

Chemical injection system

- Auxiliary peristaltic pump and tank system

- Chemical injection pump controlled by process recipe

Wide variety of accessories available

Download Brochure Request Information

Servo RS – 7600

The RS 7600 is a large production machine that can accommodate larger part sizes. This versatile machine can conduct a range of basic operations as well as multi-step and highly complex operations. The RS 7600 can support high removal rates on robust components, or it can be used for intricate/delicate components.

Machine Highlights:

- Operator-friendly features of legacy GUI

- Ease of operator use through single point load & unload

- Bottom plate and top plate rotation sync’d during unload for wafer tracking

- SECS/GEM compatible

- Enhanced safety and ease of cleaning with split enclosure

- Compatible with PRH DS Automation Cell

SSP-619

The SSP-619 is specifically designed to withstand a wide range of slurries at extreme pH levels and temperatures.

Exposed surfaces of the machine are chemically resistant to the interactions of slurries, thus improving machine cleanliness, reducing clean up time, and improving wafer quality. The SSP-619 offers innovative features and capabilities that maximize part load size and reduce dedicated operator time.

Machine Highlights

- Chemically resistant design and

- treated surfaces

- Independent polishing head rotation

- and pressure controls

- Ease of use for operators

- Convenient load/unload station

- Unique dovetail carrier design

- practical for manual mode

- critical for automation mode

- Temperature controlled processing

- Water cooled bottom platen

- SECS/GEM compliant

- Robotic cassette-to-cassette automation option available